Company News

Company News

Cold rolling of stainless steel strip is a metal processing process in which the stainless steel strip is cold treated to produce plastic deformation to achieve the desired shape and size. Specific process steps include:

1. Prepare raw materials: Select suitable stainless steel coil as raw material, and carry out surface treatment and cleaning to remove surface oxides and stains.

2. Annealing treatment: The raw material is annealed to eliminate the internal stress and improve the metal structure and properties.

3. Pickling treatment: pickling of annealed raw materials to remove surface oxidation and stains.

4. Cold rolling treatment: The raw materials after pickling are sent to the cold rolling machine for cold rolling treatment, and the plastic deformation of the metal is generated through continuous extrusion and stretching of multiple rolls to achieve the required shape and size.

5. Heat treatment: Heat treatment of cold-rolled metal to eliminate internal stress and improve metal structure and properties.

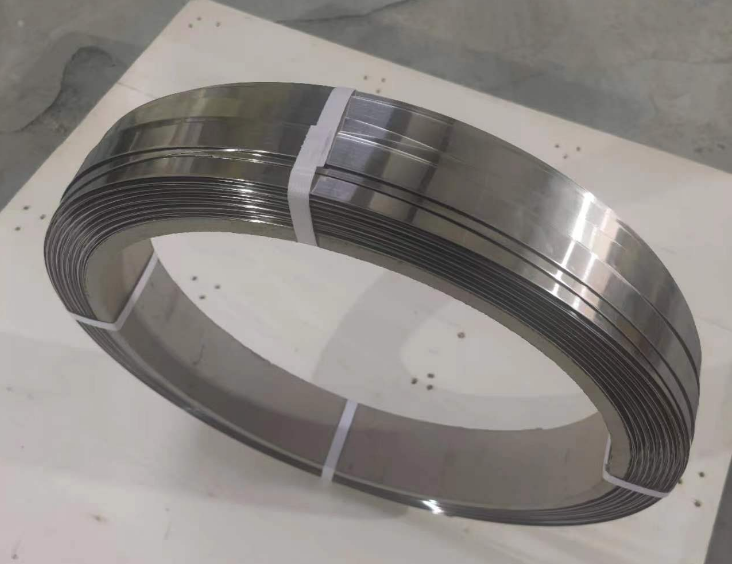

6. Cutting and packaging: the heat-treated stainless steel tape is cut and packaged as required for storage and transportation.

Stainless steel strip cold rolling has the characteristics of high processing precision, good surface quality and excellent mechanical properties, and is widely used in petroleum, chemical, medicine, food, machinery and other fields. At the same time, stainless steel strip cold rolling is also one of the important links in the production process of stainless steel products, which is of great significance for improving product quality and market competitiveness.